One of the things you need to remember when running a company, especially one with machinery or tech, is maintenance. Carrying out regular maintenance checks will ensure that your business keeps running on time and that production is high. One of most people’s issues with maintenance is not knowing where to start. If you are in such a place, worry not. With a few tips. You will be able to organize and see-through maintenance checks that will keep the factory up and running for a long time. Here is what you need to do when carrying out maintenance.

Create a preventive maintenance program

Having a preventive maintenance program will help a lot when it comes to production and maintenance. The program helps you figure out which areas need working on and which ones are okay. Often, you might be carrying out checks but not in the areas that need it. You end up with a faulty system despite carrying out maintenance checks. Here are some of the perks that come with a thorough and well-done preventive maintenance program.

- You reduce the risk of machines breaking down

- It extends the equipment value

- Reduces the cost of replacing an entire system

- You get to improve on the equipment you have

One of the things you need to remember is preventive maintenance is not similar to regular maintenance. It is thorough and should be done occasionally. It should also not replace regular maintenance since that is just as vital. Schedule this year or semi-annually so you get ahead of any issues.

Know what causes machines to break down

While you might have the money to keep replacing machinery every time, it is not viable at the end of the day. The one thing you need to do is find out what makes your machines more likely to break down. In knowing this, you can work on putting measures in place to ensure that the machines do not break down. In knowing why your machine failed, you are better placed to replace or repair it as soon as the failure happens or way before. You might need to research the type of equipment you have. That way, you get to figure out what you should be on the lookout for when your machines fail.

Train your employees

One thing many people forget is part of maintenance is employee training. If you have not rained your employees, they will not know what to expect when handling the machinery. In educating our staff, you ensure that they are prepared for any issues and will spot warning signs beforehand. You also know that there will be no mishandling of the equipment in your absence. Many of the issues that happen to equipment are because staff had no idea what to do in certain situations.

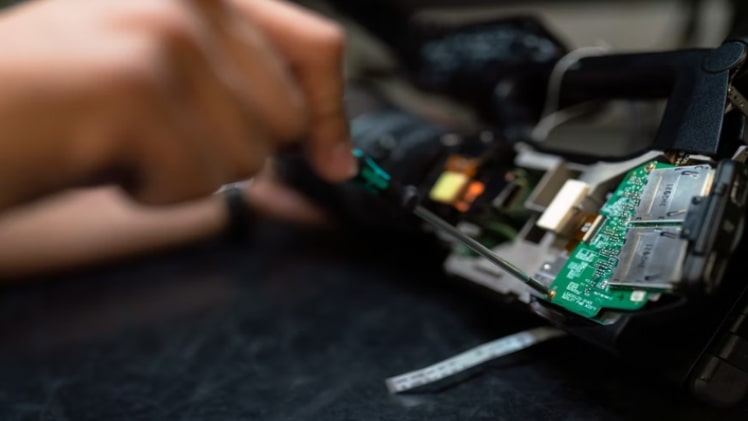

Research your machines

One of the things you will realize when you finally own a factory is the machines have so much to them. You need to take your time to know every single component of your machine. That way, if there is an issue, you can easily pinpoint it and deal with it. Many people do not take the time to figure out how their machines work and end up with a faulty machine because of mishandling them. If you cannot find something on troubleshooting in the manual, you can always check to see if there is anything on the manufacturers’ website. Knowing the machine and whatever issues go wrong will ensure that everything works together seamlessly.

Ensure you carry out maintenance at the recommended intervals

The only other thing that is worse than not carrying out maintenance is carrying out maintenance at irregular intervals. There is a reason why the manufacturer will ask you to take a thorough look at your machinery at a certain time. If you keep skipping maintenance checks because the machinery seems to be working well, you might just end up with spoilt machinery. Ensure you stay up to date with all the checks, so you catch anything before it gets worse. If you want to sync your check, you can do that at the beginning and check everything simultaneously. The only thing you need to remember is some types of machinery need to be checked more often than others. That means you have to plan for more checks for such equipment.

Keep a log of all maintenance check results

There are times when checks reveal that certain parts need changing or repair within a certain time frame. If you have no money to handle it, you might want to shelf those off. In this situation, you need to remember to pen such changes down. You might be surprised how easy it is to forget such things. Including them in a log makes it easy for you to get back to them since there is a reminder. The logs also come in handy in case there are issues with inspections. Most companies go through audits, and if you have not logged in all your maintenance and its results, you might end up with a closed factory. When it comes to logging your maintenance checks, do not worry so much about being perfect. As long as you can log in the maintenance checks and how you handled them, you will be good to go.

When it comes to your company, you need to ensure you are ahead of everything. That is the only way to keep your company working at maximum capacity. The one thing to do is to ensure you carry out regular checks and carry out repairs on what needs to be taken care of. With a regular maintenance check, you can ascertain that everything is updated. You also get ahead of any issues that might lead to production stops. The pointers above show you how you need to carry out the checks and what you need to remember to do. Follow them, and you will have no issues with your factory or plant.