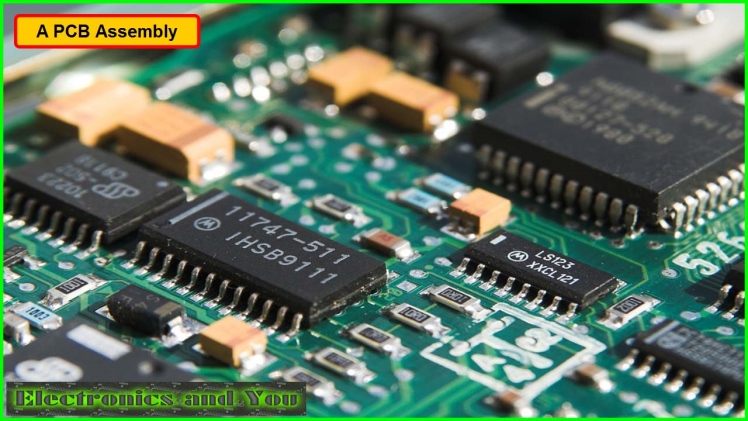

PCB is the gene of the lamp level creation of the electrical engineering region that is doing wonders every day. Each layer of the printed circuit board can hold amazing. Printed wirings through the board need the excellent collaboration of engineering and creativity Because you have to design the most efficient design within the least possible space. Then comes the outlook. Nowadays, consumers want a sleek and sexy design for their gadgets. Several tech reviewers and YouTuber unscrew the PCB boards and give an opinion if to buy it or not. So the PCB board assembly and fabrication is as crucial as the layout designing, painting, and adding to the board.

Assembly Process Of PCB

At first, comes the solder pasting. Marking the areas that need to solder pasting by applying a solder screen is the preparatory process. In this way, you keep the places that require soldering. The solder paste is a mixture of flux and solder material. The solder screen is made up of the design layout of the running PCB. So, it has holes following the solder pad, SMT pad, etc. Then press through the board with the runner squeezing a little mount substance on the way. You have to control the amount yoof solder mixture is depositing on the board. It will determine the accuracy and frequency transmission rate of the PCB board. After this process comes the pick and press level. Here a big machine which is loaded with the essential components you need in the board comes forward. With the help of a pre-programmed design, the device picks up the materials and puts them in the soldering pads. Usually, the materials get hold by the surface tension of the PCB board. But in some manufacturing facilities, they use glue dots to hold the things in place. But, the major drawback of this fixation is that the glue makes any repairment work difficult. However, some factories use temporary glue that dissolves during the soldering process. Before, the wave soldering technique was prevalent. But in this process, you have to put extra solder paste to run the machine, which is hectic. Nowadays, a reflow soldering machine is most widely used. After the soldering process, the PCB chips go for inspection. Thorough physical check-up and testing with several electronic devices will pass the engineer in charge of the fabrication process. While if you are also interested in the fpc manufacturing process, this could be a good instruction for you.

PCB Fabrication

The PCB fabrication process refers to bring the designed layout to life. That means applying the boards and circuits to an opt device and test it to see if that works properly. Factories have a test and measurement facility to ensure all the parts and courses are correctly fit and giving accurate results. Record the feedback and use the data to improve every time you make a new slot. Because the everchanging electronic world needs more engagement and better performance in a smaller, portable device, if you are an aspiring electrical enthusiast, then you can buy the primary elements in the nearest PCBA store to develop newer dimensions to the board and learn more.

Conclusion

The printed circuit board is the future of electronics. The more evaluation the industry goes through, the better performance and adjustments the PCB chips will need. Because right now, size, portability, and resource efficiency matter the most in the world. If you are not developing with the era, then you must get out of the stream. So, it is time to take a better look at the PCB assembly and alignment. Nowadays, several computer-automated designing softwares can choose the best possible assembly design for your PCB board.