Many business owners are choosing alternative materials to heavy materials. It’s happening as technology is getting more advanced nowadays. The popularity of ULTEM 1000 plastic is getting popular among various industries. If you want to contact a ULTEM 1000 supplier, you need to know more about this plastic.

Polyetherimide or ULTEM 1000 is one of the most popular thermoplastics right now. In the following, we are covering the top five machining tips for this plastic. No matter if you are starting a small business or you are a part of a huge industry, these tips will be helpful for you. Let’s find out.

What is ULTEM 1000 Plastic?

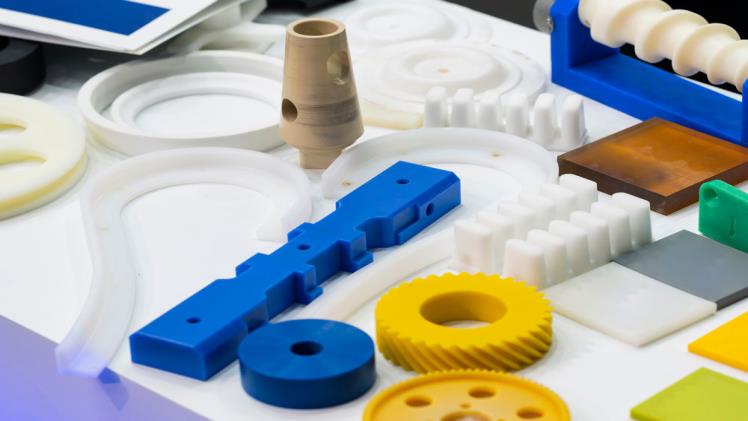

As we noted above, ULTEM 1000 is a premium quality plastic that can be used as an alternative to heavy metals including aluminum and steel. In simple words, ULTEM 1000 or polyetherimide is a thermoplastic. Moreover, this plastic has similar characteristics to PEEK plastic.

Many industries are using ULTEM 1000 sheets as an alternative to traditional heavy materials. ULTEM 1000 is very popular in the 3D printer industry. However, many people are using this plastic for heavy construction as it can give a long-lasting performance.

ULTEM 1000 Machining Tips

Now, you know what ULTEM 1000 is and why many industries are using this plastic. If you also want to use this plastic, you need to know about the machining tips as well. Let’s find out about the top ULTEM 1000 rods machining tips:

1. Turning

When you are starting the operation, ULTEM 1000 plastic requires positive geometries. On the other hand, ground peripherals can help you reduce material build-up on the ULTEM 1000 plastic insert. You can also use a C-2 carbide for this insert operation.

2. Drilling

No matter what you are making, drilling is an essential machining tip for ULTEM 1000 plastic. Well, you need to know about the characteristics of this plastic during the drilling operation. It’s more essential when the depth of the hole is huge.

3. Threading and Tapping

In some cases, many industries need threading and tapping for ULTEM 1000 plastic machining operation. You can start this process by using a carbide insert. Some experts also suggest coolant usage for this operation. However, you need to use a specified drill for tapping.

4. Sawing

Sawing is also essential for irregular cuts. If you want straight cuts, table saws are the best for it. Hence, they can be used for cutting multiple thicknesses. Make sure you are choosing the saw blades as per the thickness of the material.

5. Coolants Tips

As we mentioned above, coolants are essential for ULTEM 1000 drilling operation. Moreover, it’s very good when you are using notch-sensitive materials. It can also minimize localized parts.

Conclusion

As you can see, knowing about machining tips is essential when you are choosing ULTEM 1000 plastic. We have covered the best machining tips in this article. If you need to know more regarding polyetherimide, you can contact an expert. On the other hand, you can also start your research.