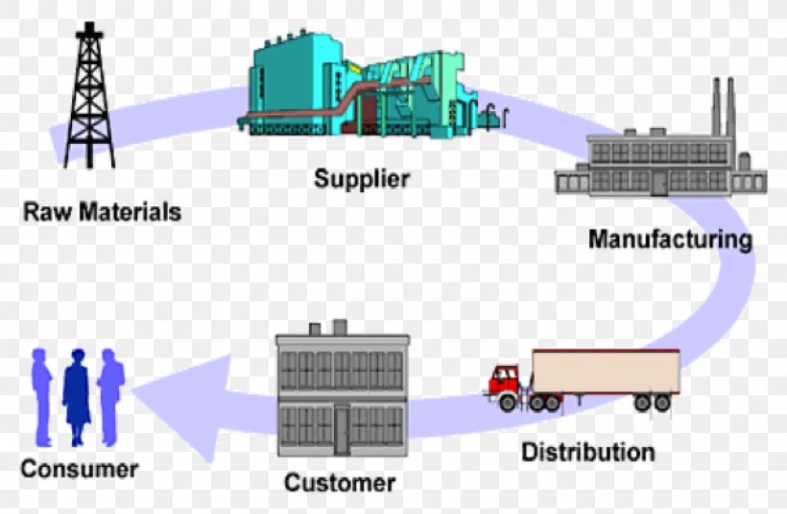

Supply chain integration is the buyers’ and sellers’ cooperation with the aim of benefiting from the relationship. This chain partnership results in improved quality, delivery, and bottom line for everyone involved in the cooperation. Additionally, the final customers enjoy the benefits of better quality, on-time delivery, and more responsive services.

In other words, supply chain integration is a communication between a buyer and a seller to establish an ongoing relationship for a better understanding of the buyer’s needs by the supplier. It usually takes the form of an integrated computer system. For example, the supplier’s computer system can be set up to deliver real-time data to the buyer’s computer. This is important to the buyers as they’ll know:

- The status of all orders

- The products in the supplier’s inventory

- The current conditions of all orders

- The status of the products that are manufactured for the buyer

- When the product is ready to be shipped

- Tracking of the product shipment

Buying from an online retailer is a simple form of supply chain integration. You can easily and immediately see whether the product is in stock. After placing an order, you’ll be notified when the order has been received, when it’s ready for shipment, and when it has been shipped.

Elements of supply chain integration

There are four main components to a successful supply chain integration including:

Communication

Communication is the key element to a supply chain partnership. Everyone in the cooperation needs to be well informed. This allows members to adjust their operations to meet demand changes and new business opportunities. It is usually done using integrated computer systems. However, there should be direct channels of communication between the key people.

Customers

The main objective of this cooperation is to meet the final customer’s needs and values. This needs the organization to establish a close relationship with its customers. Also, the lead organization needs to make others aware of the final customers’ needs. In general, everything should be focused on the customers’ needs as they’re paying the bills for everyone in the supply chain.

Collaboration

To be successful and even effective, supply chain members should have a good relationship. Every member should be interested in developing their suppliers. This may involve providing training to improve their product knowledge and understanding of the market. Moreover, they can be involved in joint product development projects. Therefore, supply chain integration is collaborative cooperation.

Cooperation

To be successful, members need to share the supply and demand information. This may include proprietary information. Without close cooperation, members may lack the information they need to respond to the customers’ needs.

Benefits of supply chain

End to end (E2E) visibility

Supply chain integration partnership creates cohesion and connectivity throughout the entire value chain – procurement to production planning to logistics. Supply chain integration ensures that each function does not exist in its silo. This is done by bringing them together to promote collaboration and decrease disconnect. The entire process is done through an IT solution that centralizes cross-operation data. Furthermore, it can be achieved through other means, but the result must be a great increase in cross-operation visibility no matter how it is achieved.

Flexibility

As in the above benefit, an integrated supply chain can help to smooth out the functioning of the day-to-day supply chain, but does it have any effect on disruption management? Since integration is increasing the knowledge and the available resources to each organizational unit, the newly accessible resources could be leveraged to alleviate crises. If, for example, your production planners are encountering a breakdown and may affect meeting demand, an integrated environment would position them to work with managers from the inventory department to develop strategies that maintain the existing shipments. In the meantime, the production workflow can be tailored to produce on parts that don’t need the questioned machine. This allows the organization to make up the difference without much wastage of time. The ability to change plans to suit new realities is always not available in more siloed environments.

It reduces wastage

Reduced wastage is another benefit of keeping your various teams working together. This is the truth because teams are no longer considering redundant processes. In a non-integrated environment, two teams may each have a dedicated less-than-full truckload (LTL) scheduled regularly. Sending less-than-full truckloads rather than just one full truckload (FTL) is wasteful and easily avoidable in an integrated environment that gives insight into the other. Various teams within an integrated supply chain should work together. Through this, they can bundle shipment, find new efficiencies, and uncover areas of redundancy and waste.

Centralization of data

Talking of uncovering areas of waste and redundancy, we slightly talked about increased data visibility that an integrated environment can afford. Much of this can come in the form of establishing a centralized cache of highly accessible information. While data centralization is good in its own right, it significantly allows for advanced analytics workflows that can help you discover areas of efficiency within your existing operations.

Improved profit margins

Each of the above benefits can have a measurable positive effect on profit margin. Improved collaboration can save money through reduced warehouse space and generally lean supply chain management. Flexibility can help you maintain value during unexpected late shipments. In other words, both of these strategies can significantly reduce your costs. In this way, supply chain integration can create room for more profit operations.

Improved cash flow

The above benefits allow companies to make the right decision, choose the right partners, and respond to market demands. Additionally, they improve the company’s bottom line.

For instance, working with reliable means fewer destructions and satisfied customers. But that’s not all. It allows you to invoice, improving cash flow.

Also, implementing cost-effective strategies to eliminate wastage of funds translates to positive cash flow.

The bottom line

In today’s complex and digitally driven supply chain, smart integration is important to stay competitive. Members need to collaborate to meet final customer needs. Also, there must be transparency and communication for members to adjust their operations to meet market changes and new demands.