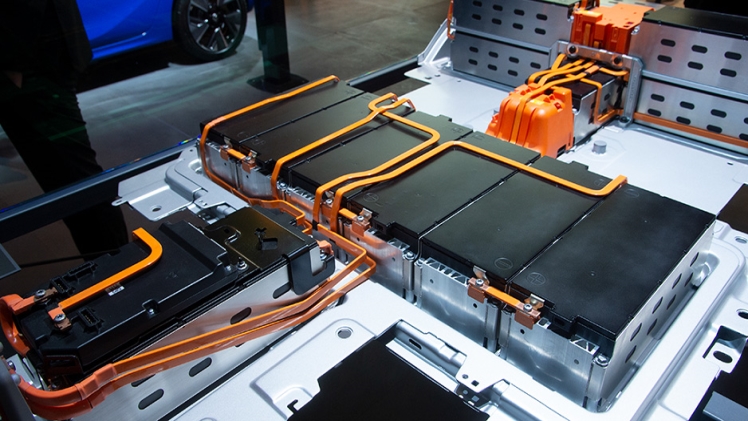

Over the previous decade, the expanding automotive industry Electric Vehicles (EV) was an essential factor. Given the continuing interference in automotive industry with the influence of green technology, a number of famous high-scale operators have indicated their aim, by 2035, to cease gas and produce electric vehicles alone. The enormous market shift led to the growing relevance of power batteries for automobile manufacturers.

In order to minimise flammability, enhance the dielectric resistance and protect against unfavourable conditions, a secure battery must be packaged with special materials for electric vehicles. TPC Packaging Solutions offers a wide variety of high quality EV battery tape, adhesive and encapsulant products as a leading industry specialist in packing.

Our Tapes for EV Batteries

The producers of electric car battery rely on high-quality tapes, adhesives and enclosures in order to maintain and protect electric car batteries from components. They are suitable for isolation, adhesive and structural support especially for severe operation of the battery EV TPC E-Packer and adhesive. Our skills include:

Cell-to-Cell Bonding

Simple, two-sided, press sensitive adhesive bandages ensure the structural integrity of your EV battery. You can safely and securely link battery cells together for secure and dependable battery operations with a selection of battery designs including dielectric and flame resistant patterns. For sound damping adhesive, please visit our site.

Compression Pads

Vibration prevention and EV movement influence on EV cells. EV mobility is constrained by compressor pads. The battery consists of electrical batteries and battery cells, and each cell is fitted with foam-sensitive sticky foam pads. The glue system is high pressure.

Thermal Runaway Protection

Strict criteria and preventative rules for thermal runaway systems should be met by electric car battery providers. Flammable adhesives and individual or double-coated film tapes such as ceramic fibre and mica are connected to UV batteries to protect these materials against thermal ruptures.

Thermal Interface Materials (TIMs)

TIMs are attached to the heat sinks or chiller panels for easy transmission and improved regulation of EV battery temperature. Our fire retarding adhesives and pressed silicon and acrylic adhesives guarantee good adherence to the TIM to enable an optimum thermal transfer. If you are looking for BLU adhesive, please visit our site.

Pack Seal & Gasketing

For safe and dependable electric batteries, tight seals in gasket assemblies are required. With our wide range of heat and pressure-sensitive cables, you can construct a trustworthy display that tightly links to the power source, prevents the infiltration of water, fluids and particles.

Flexible Busbar Adhesives

Flexible circuits incorporate several EV components of the battery. The electric insulated bar and flame protection are covered by our double-coated, inflammatoric adhering solutions.

Electrical Insulation

In order to protect the components against electric current fluctuation and electromagnets interference, the EV battery consists of separated cells. Tapes can be used directly with a single and double façade to place moisture compression pads and other insulation materials on dielectric-filmed components.

Cell Wrapping

In single or double-coated dielectric sheets, EV cells can be wrapped, insulating sensitive constituents from electric currents.

PET Film for EV Battery

Vibration impacts, stress, humidity, corrosion and chemical solvents by cell encapsulation or isolation are reduced. Cell Encapsulation It also reduces heat flushing, heat transfer, flame transfer and insulation. Terephthalate or polyethylene is highly praiseworthy to satisfy the critical industrial need for inflammability, dielectrical characteristics and PET film. While many suppliers provide tapes and adhesives in their respective nations, few supply the TPC PET film embossment.

Our own experience entitles us to convert diverse materials to manufacture prototypes, production enclosures and heating sealing films that meet and exceed our comprehensive range of dielectric diecutting and production devices, UL 94 V-0 and ASTM D3755.

EV Battery Tapes

We use cutting-edge technology and advanced materials to manufacture belt, adhesive and capsule solutions that satisfy every high level of EV battery. In each application, we have over half a century of know-how to offer individual packaging.